Kouvola, Finland / DG21R/DG16R

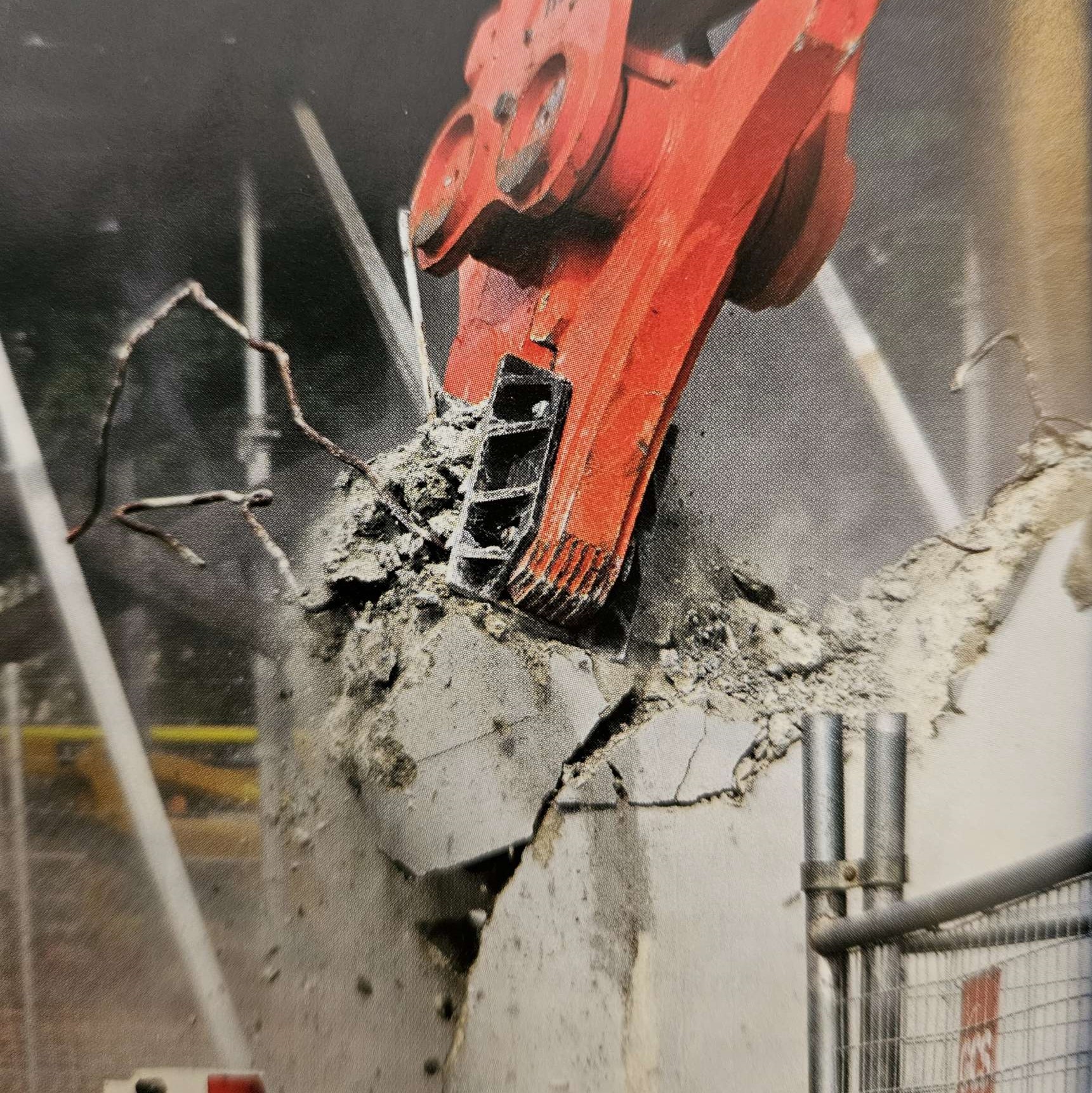

Robi grapples work hard for the money

Ekokaari Oy is located in the Keltakangas waste recycling centre in Kouvola Finland. Ekokaari provides the Kymenlaakso based companies with a wide range of waste handling services, which include construction and energy waste processing, waste storage services etc. In addition to an efficient crushing and sorting line, pre-sorting machines are also needed. Robi demolition and recycling grapples (later Robi grapples) play an important role in excavator-assisted sorting, crusher feeding and car loading.

Ekokaari’s recycling area in Keltakangas is about 20 hectares in size. The total area of the waste centre is about 100 hectares. The annual amount of waste processed is about 50,000 tonnes and it contains a very diverse range of raw materials. The current trend is that as little as possible of incoming materials is disposed of. Further processing of different materials or crushing them for energy use are also daily tasks here.

Purchased in 2020, the tracked Teuton Z60 mobile crusher, weighing approximately 32 tonnes, has been in heavy use. It is suitable for crushing wood, construction and demolition waste etc. Ekokaari also crushes various plastic materials, furniture etc. “Teuton crusher is omnivorous, however, we no longer crush certain materials. Thick mooring ropes from the ships are one of these impossible materials to crush. If the crusher takes 40 litres of fuel per hour for that job, and the supply from the conveyor is only one tonne per hour, then it’s not worth it,” says maintenance foreman Samu Korjala in February 2023. At the time of the visit, pressure-impregnated lumber and furniture, such as sofas and frame mattresses, were fed to the crusher. Teuton munched them easily and the result is the wood chips for energy use.

A Robi DG21 grapple (weight is 1 300 kg) is attached to the wheeled Volvo EW240E material handling machine that feeds the crusher. Volvo with Robi grapple is also used to load high sided cars. The cab of the Volvo can be elevated. That makes it easier to see both the jaws of the crusher and the platform of the car. The smaller tracked Volvo EC160EL excavator has a slightly lighter Robi DG16 (weight is 985 kg) as a tool.

The suitability of Robi grapples for light demolition work was confirmed when a tracked Volvo attacked an old construction site barracks. That was quickly shattered to a thousand pieces. The wood and the metal were separated effectively.

Ekokaari also has an efficient and modern mixed waste processing line in the area. Different particle sizes and materials are separated in different stages. The Robi grapples are pre-sorting materials for this processing line.

“We strive to recycle all the material that is suitable for further use into energy production”, continues Korjala.

Robi and Volvo make sense

In total, Keltakangas has seven Volvo branded machines, three of which are wheel loaders and the rest are excavators/material handling machines. Robi grapples are trusted tools. The oldest Robi grapples are from 2016.

“These grapples from the new collection came with the Volvo’s. The material handling machine now has about 2 200 hours on the meter and the other one has just under 2 000 hours. The grapples have been connected to Volvo’s the whole time, which means they have been working for the same amount of time as the basic machines”, say machine operators Mika Suortti and Juuso Laaksonen.

“The accuracy in these is very good. I like that when closing the grapple, the jaws match vertically with very high precision. The correctly designed geometry guarantees that the machine’s boom does not need to be adjusted while closing the jaws. It speeds up the process and makes work easier,” says Laaksonen.

Both operators are very experienced. Picking different materials from a pile is accurate to the millimetre and shaking seems to be a useful movement when separating different materials from each other.

“In the new grapples, the jaws are moved by synchronizing rods that run crosswise to each other, not parallel. This results in high precision in the jaws. The trajectory has also been slightly changed to achieve maximum pressing force. The structure has also been reinforced throughout. The hydraulic cylinder is stronger in the new model series. The bearings are maintenance-free”, says Miika Janhunen from Ramtec Oy.

Special bearings used by the mining industry are also available for grapples used in heavy two-or three-shift work. The plate lips are bolt-on and reversible. At the beginning, the new plate lip rests against the chin and reduces the load on the bolts. After turning, of course, there is a gap between the plate lip and the chin.

Manufactured in Lahti Finland

“In this larger DG21 grapple, rotation is accomplished by two hydraulic motors. We recommend using a leak line. That and the shock valve protects against hydraulic pressure shocks, and together guarantee that the seals have a long service life”, promises Janhunen.

Ramtec assembles the grapples at the Lahti factory. The grapple models DG16, DG21 and DG31 use many identical parts, for example, same bearings, hydraulic cylinders and motors. It improves synergy with the customers as well as maintenance and assembly. The DG31 model with a double cylinder was presented at Bauma 2022.

“We recommend a maintenance and inspection interval of 800 hours. The grapples that come back to us for maintenance are first tested and the clearances are checked. Pins and bearings are checked also, possible leaks are repaired and the plate lip is replaced if necessary. In time preventative maintenance ensures that the work is not interrupted at the sites”, concludes Janhunen.

Orginal release: Konepörssi/ Olli Päiviö