Robotic welding station reduces manual work from the Estonian company Harry Metall OÜ. The station’s automated technology enables a high-quality final product and increases production capacity with optimized welding processes.

The Estonian contract manufacturing company, Harry Metall OÜ, is situated in Rannu near Tartu, Estonia. The company was founded in 2001 and bought by a Finnish company, Ramtec Oy in 2010. Today, Harry Metall operates in a new, modern factory as a contract manufacturer for various companies, producing a range of products including different mining and earthworks buckets. Their main customers are export companies from Finland, Sweden, and Estonia. The investment in welding automation equipment was part of Harry Metall’s future strategy for developing its products and aims to be strong and competitive in growing and highly competitive markets.

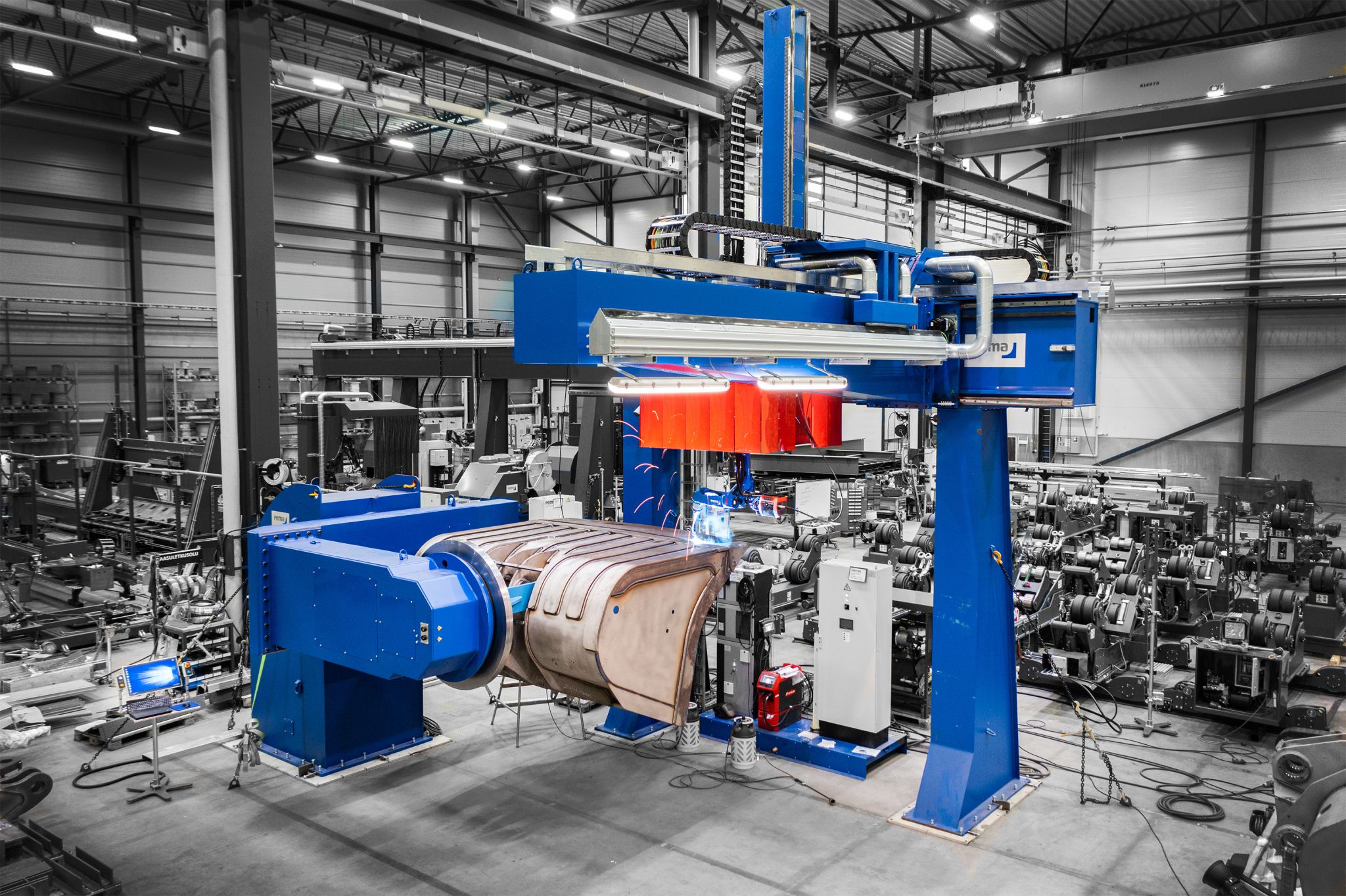

“Thanks to the modern PEMA welding solutions, we now have a higher level of automation, and the robot station increases our productivity significantly. The station’s automated technology reduces manual work, producing a high-quality final product. The welding processes are optimized which also increases the production capacity”, tells Veikko Janhunen, Chairman of the Board at Harry Metall OÜ.

Committed to delivering high-quality products to its customers, Harry Metall realized the need to find new ways to stay competitive. The aim was to find a solution that would bring improvements and efficiency to the heavy manufacturing process.

“One of our main goals was to reduce manual work. The lack of welders is a global challenge. We wanted to add automation to our processes, increase quality and stay competitive. This robot station together with multi-pass welding brings us the flexibility and volume we were looking for.” says Harry Salu, General Director at Harry Metall OÜ.

The total delivery from Pemamek to Harry Metall included a robotic welding station with three external gantry axis, 10-ton 2-axis workpiece positioner, PEMA WeldControl 300 offline programming and five welding programs for different products.

Thinking about the investment in welding and production automation in the long run, the aim is to gain a competitive advantage. Flexibility, cost savings, and the ability to manufacture big volumes with less manual welding combined with increased quality are something Harry Metall finds extremely valuable.

“We have calculated that the payback time for this investment is less than 3 years. We have already been thinking about the next investment in automation. One option that has been on the table is another robotic welding station”, tells Janhunen.